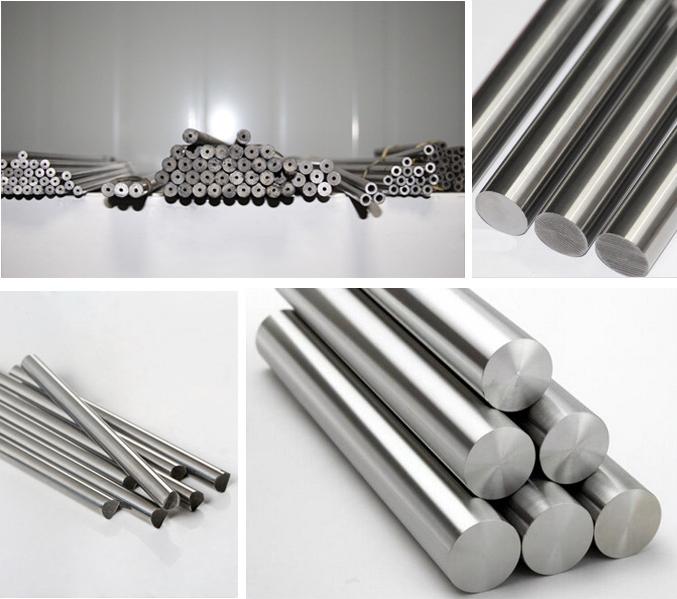

Tungsten Carbide tsvimbo ndeye tungsten carbide kutenderera bar, zvakare inozivikanwa se tungsten simbi bara, nyore kutaura, tungsten simbi bar kana tungsten carbide rotenderedza bar. Tungsten Carbide Chinyorwa chinogadzirwa neupfu mitallurgy uye chakaumbwa neyefreta yesimbi makomputa (yakaoma chikamu) uye yakasungwa simbi (binder chikamu).

Pane nzira mbiri dzekugadzira dzekugadzirwa kwe tungsten carbide kutenderedza mabara: imwe yakawedzerwa, uye yekuwedzera inzira yakakodzera yekugadzira mabara marefu. Inogona kuve yakagadziriswa kune chero urefu inodiwa nemushandisi panguva yekuwedzera maitiro. Nekudaro, kureba kwese hakugone kupfuura 350mm. Iyo imwe ndeyekumanikidza kuumba, iyo inzira yakakodzera yekugadzira pfupi bar stock. Sezvinoratidzwa zita, simended yemari yekadzi inodzvanywa mune chimiro neumbwa.

Carented carbide ine nhevedzano yemhando yepamusoro yakadai seyakaomesesa, pfeka zvakanyanya simba, simba rakanaka, kunyanya kupokana nekudziya kwe500. Tungsten Carbide inoshandiswa zvakanyanya sezvinhu zvekushandisa, sekutora zvishandiso, zviga zvesimbi, graphled simbi, uye simbi yakakwira mangange .

Zvidzitiro zvezvinhu zvakanyorova zvakanyorova, kuomesa, glue dowing, wozomisa kuderedzwa mushure mekuumbwa kana kuumbwa, uye pakupedzisira kugadzira iyo yekupedzisira lead nekukuvara nekuchinjisa.

Iko kukanganisa kwekutenderera kwekutenderera kwekutungamira kwekugadzirwa ndiko kuti kutenderera kwekutenderera kwakareba. Kucheka zvidiki zvidiki zvekutenderera matende pasi pe3mm uye kutyora iwo maviri magumo kuchatambisa imwe huwandu hwezvinhu. Iyo yakareba kureba kweiyo kabhokisi kabhokisi diki diamita kutenderera bar, zvakanyanyisa kutapira kweisina chinhu. Ehezve, zvakananga uye zvinetso zvekutenderera zvinogona kuvandudzwa nekukwevera kwechiratidzo panguva imwe chete.

Imwe ndeyekumanikidza kuumba, ndeipi nzira pfupi yebhari yemari inogadzirwa. Sezita rinoratidza, iyo chiumbwa chinokotamisa carbide carbide poda mune chimiro. Iko mukana weiyi bar bar yekugadzira nzira ndeyekuti inogona kuumbwa mune imwe chete yekupfuura uye inoderedza scrap. Ruramisa iyo waya yekucheka waya uye kubvisa iyo yakaoma zvinhu zvekutenderera kweiyo nzira yekuwedzera. Nguva yakapfupiswa pamusoro inogona kuchengetedza vatengi mazuva manomwe.

Kutaura zvakanyatsonaka, kuchamanikidza kunoparadzanisa ndekwekumanikidza kuumba. Ostatatic kumanikidza ndiyo yakakodzera nzira yekugadzira yekugadzirwa kweakakura uye yakareba tungsten carbide kutenderedza mabara. Kuburikidza neyekumusoro uye wepfupi piston zvisimbiso, pombi yekumanikidza inokanganisa svutugadzike yemvura pakati peiyo silinder

Kutumira Nguva: Jan-24-2024