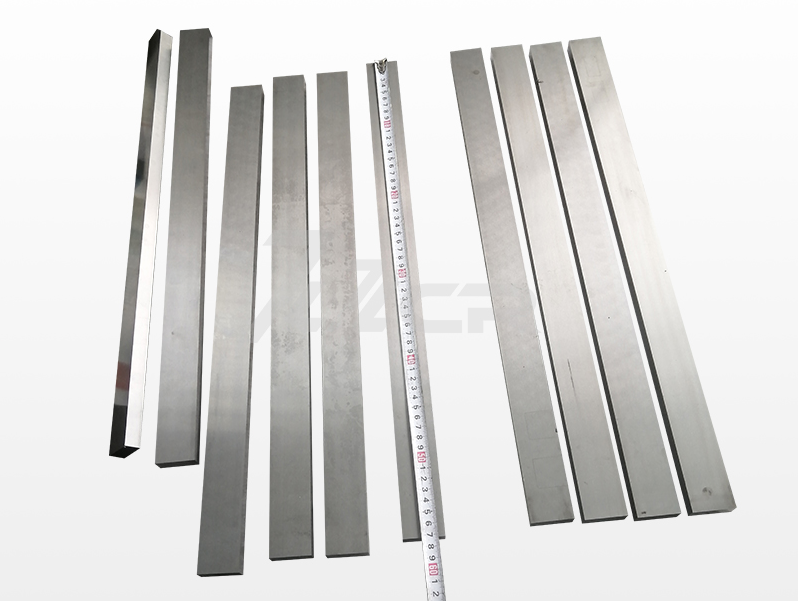

Tungsten Carbide Strip inonyanya kugadzirwa neWC Tungsten Carbide uye Co Coballat Powder neWC uye COPLASE SEASS YAKASHANDISA TUNGSTEN CARTP haina kufanana, uye huwandu hwekushandiswa kwakanyanya.

Chimwe chezvinhu zvakanakisa zve tungsten carbide mitsetse, inotumidzwa nekuda kweiyo rectangular chimiro chemapurati (kana materu), zvakare anozivikanwa se tungsten carbide strip / mahwendefa. Tungsten Carbide Strip ine hutsinye hwakanakisa, zvakanaka kupokana, simba repamusoro, rakanyanya kuomarara, kuwedzera simba, rinodziya uye magetsi maitiro akafanana nesimbi uye magetsi.

Ndezvipi zvikonzero zvedesoldingeringye tungsten carbide mitsetse? Chuangrui carbide ichapindura inotevera:

(1.

(2)Desoldingeringzvichaitikawo kuti mumiririri ane simba asina kusarudzwa uye akashandiswa zvisina kufanira, semuenzaniso, apo Borax haagoni kuita deoxidizing basa, uye zvinhu zvine hungwaru hachina kunyatsonaka pamusoro peiyo yakadzikiswa pamusoro, uye iyodesoldingeringphenomenon inoitika.

.desoldingeringichaitika kana tembiricha yakanyanya kukwirira kana kuderera kwazvo. Kupisa zvakanyanya kunogona kukonzera oxidation muWeld. Uchishandisa zinc-ine simbi yekushambadzira ichapa weld weld bhuruu kana chena ruvara. Kana tembiricha yekushambadzira yakaderera kwazvo, ild weld ichaumbwa, uye mukati meWeld ichange yakafukidzwa nenjodzi uye yekushambadzira. Mamiriro maviri ari pamusoro apa anoderedza simba reWeld, uye zviri nyore kuti ubwe kana wakarodzwa kana kushandiswa.

Kutumira Nguva: Aug-28-2024